Further Reading

Here is additional information which supports my Spring 2021 MS Capstone Project through Duke University’s Pratt School of Engineering.

What is a Composite Material

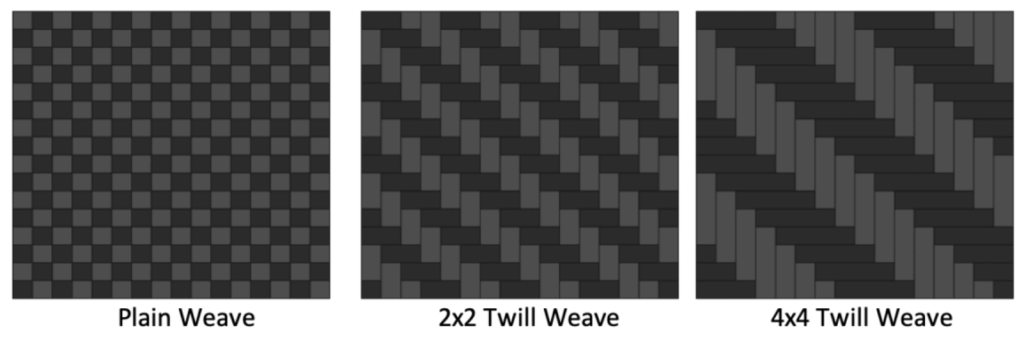

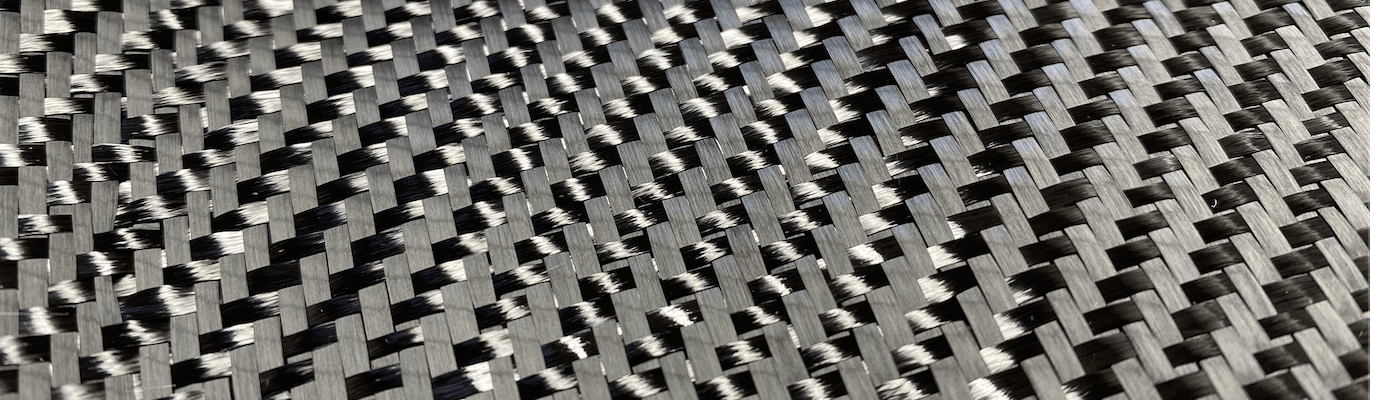

Composite material fabric, or “ply”, is produced in a variety of configurations. The below diagram from CA Composites Ltd. shows the differences between a plain weave, which looks like checkers, and a twill weave, which progresses along an angle. The foundations of each weave are the flat bundles of extremely fine fibers which create the patterns seen below.

The number of individual strands per bundle is referred to as the ‘tow’, and this value can impact the strength, application, and aesthetic of a ply. In general, the hardening of these fibers within a matrix material (such as an epoxy resin) is what enables the cured component to have improved tensile and compressive strength relative to that of the fibers or matrix material individually. Further reading on the exact math for different cases of anisotropy can be found here from the University of Auckland department of engineering. This resource outlines constitutive relations, compliance matrices, and the varying levels of anisotropy in greater depth.