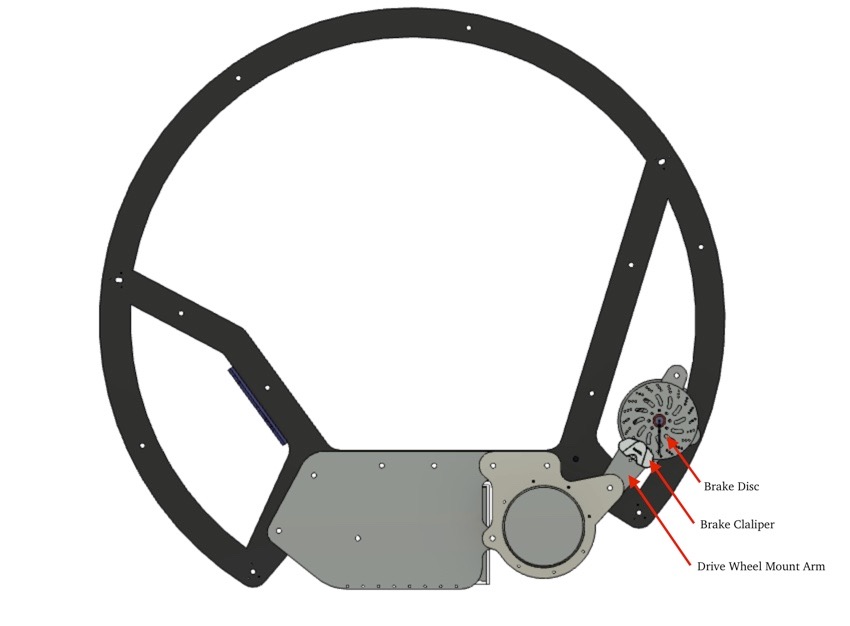

This is a continuation of a series of posts about the EV360 Electric Monowheel Vehicle, a student-led project through Duke University’s Innovation CoLab.

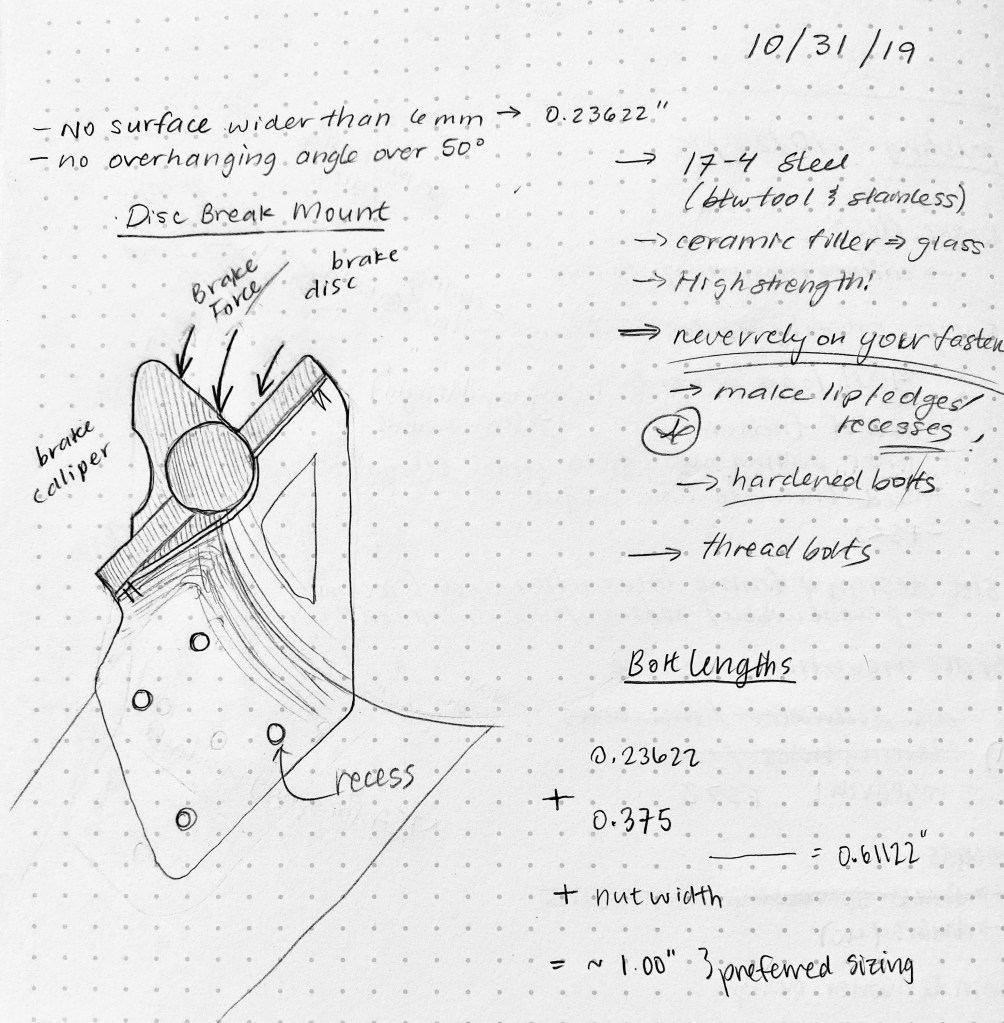

Due to the unique shape of the mount, machining the mount on the mill out of steel would have been far less time efficient than metal 3D printing the part from SAE type 630 / 17-4 stainless steel. I had started learning more about the design constraints of metal 3D printing and therefore was the most prepared of my teammates to take responsibility for the component’s development for this manufacturing method.

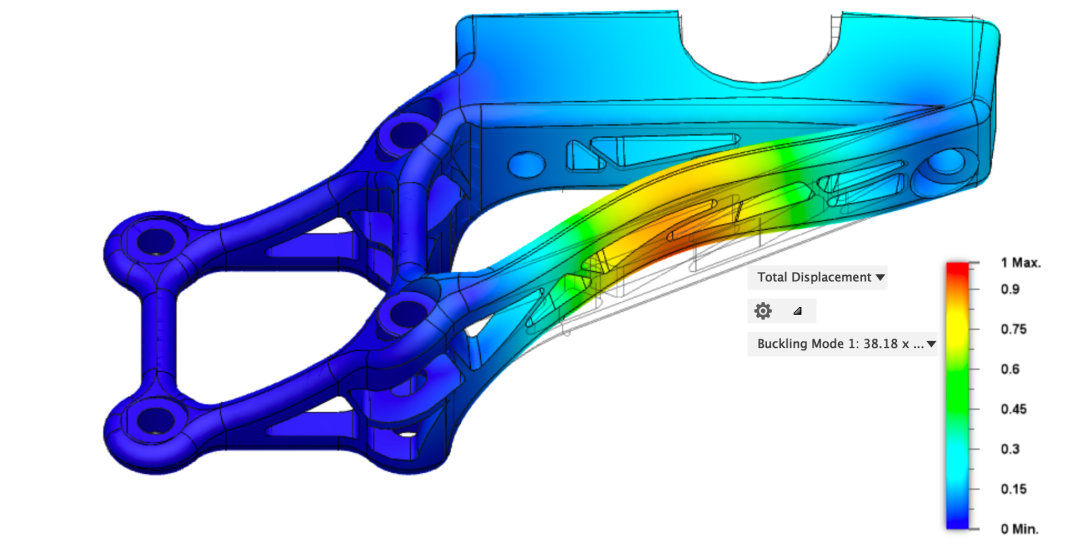

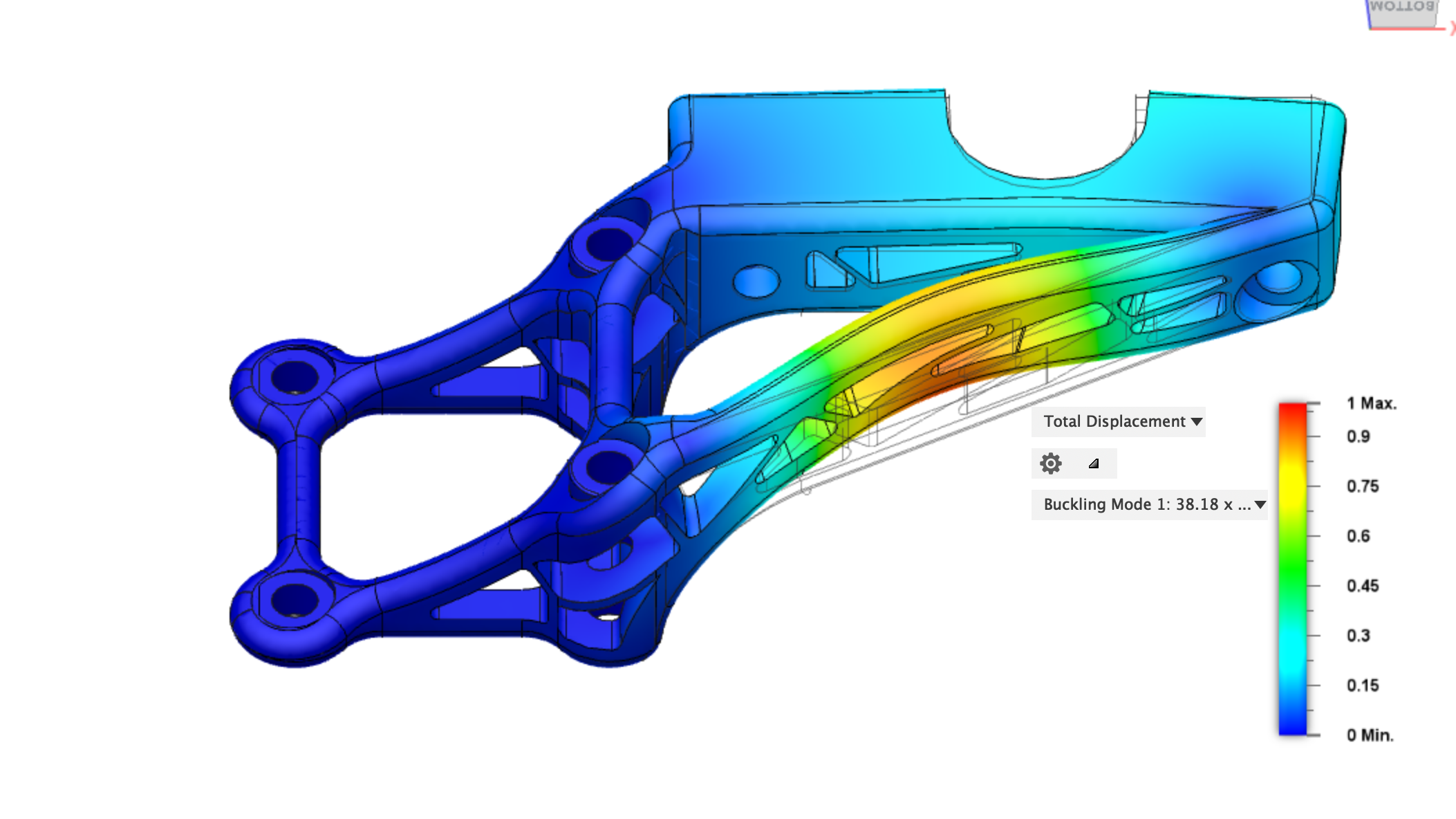

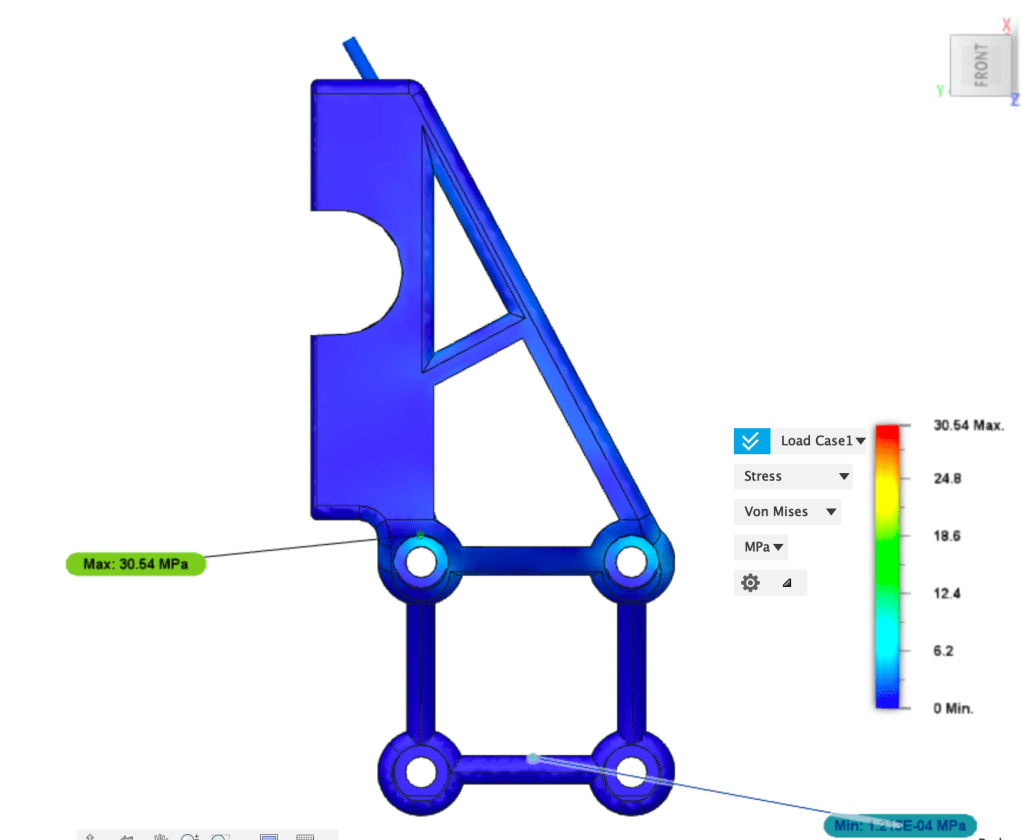

After some initial CAD work in Fusion 360, I ran some basic simulations to understand where the most vulnerable points of the component were (keeping in mind that the material properties of 3D printed metal differs significantly from that of solid stainless steel alloy.

The diagonal truss clearly suffers the greatest deflection with the lowest factor of safety. For this reason I edited the component design to include a supporting beam which significantly reduce the bending stress in the diagonal beam:

As our design changed to include a more robust brake disc caliper, the caliper mount design became much simpler and much easier to manufacture. Nevertheless this was a very useful and interesting exercise in learning about metal 3D printing and practicing DFM according to the unique limits of this manufacturing method.