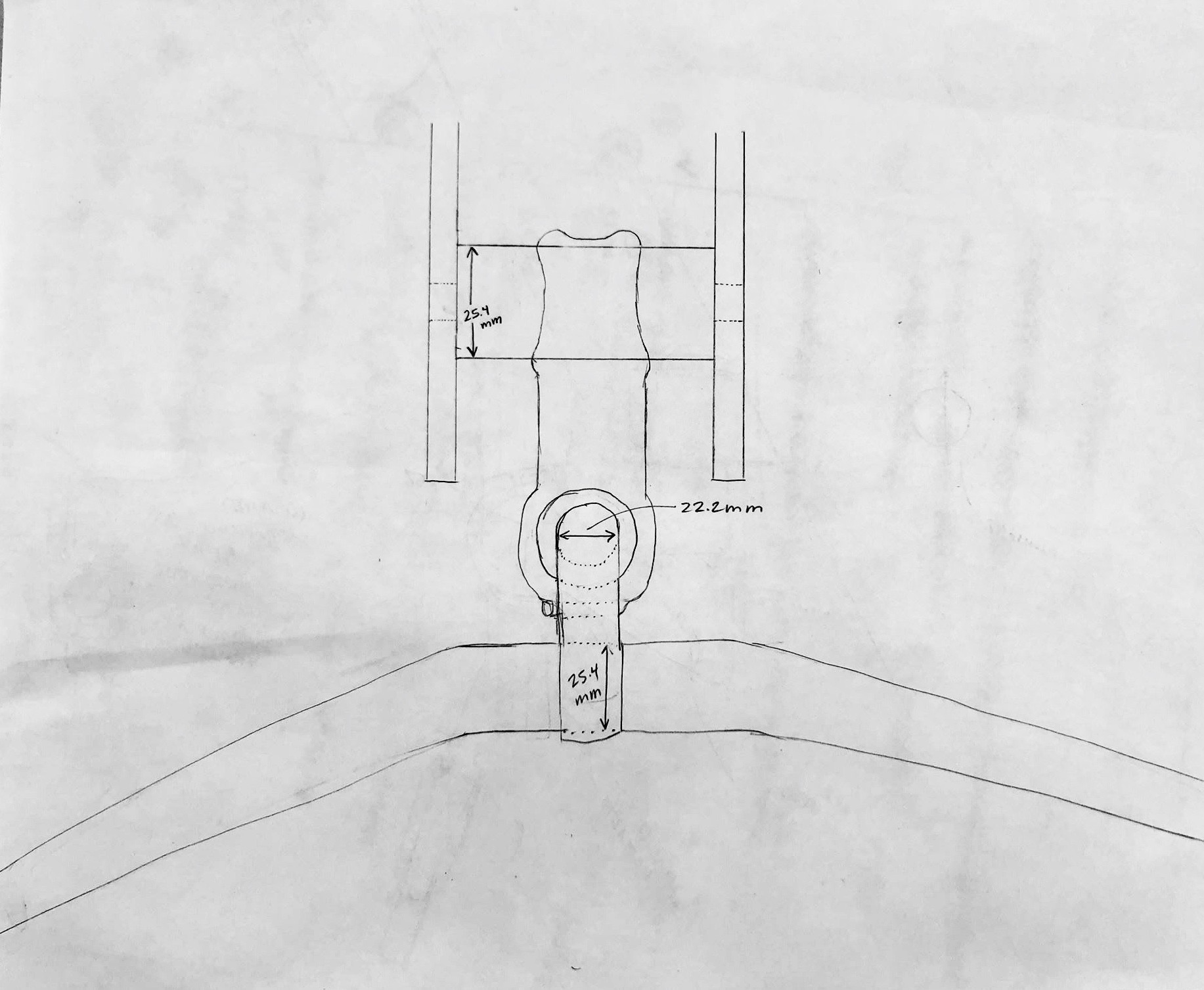

One of my responsibilities during late August and early September 2019 was to find or design a secure mount for the standard mountain bike handlebars that were found at the local bike Coop. After having chosen the handlebars and stem, I set to work designing a mount for the bars which would allow the driver to self-stabilize. The bars also serve as a spot to attach the motor throttle and brake lever.

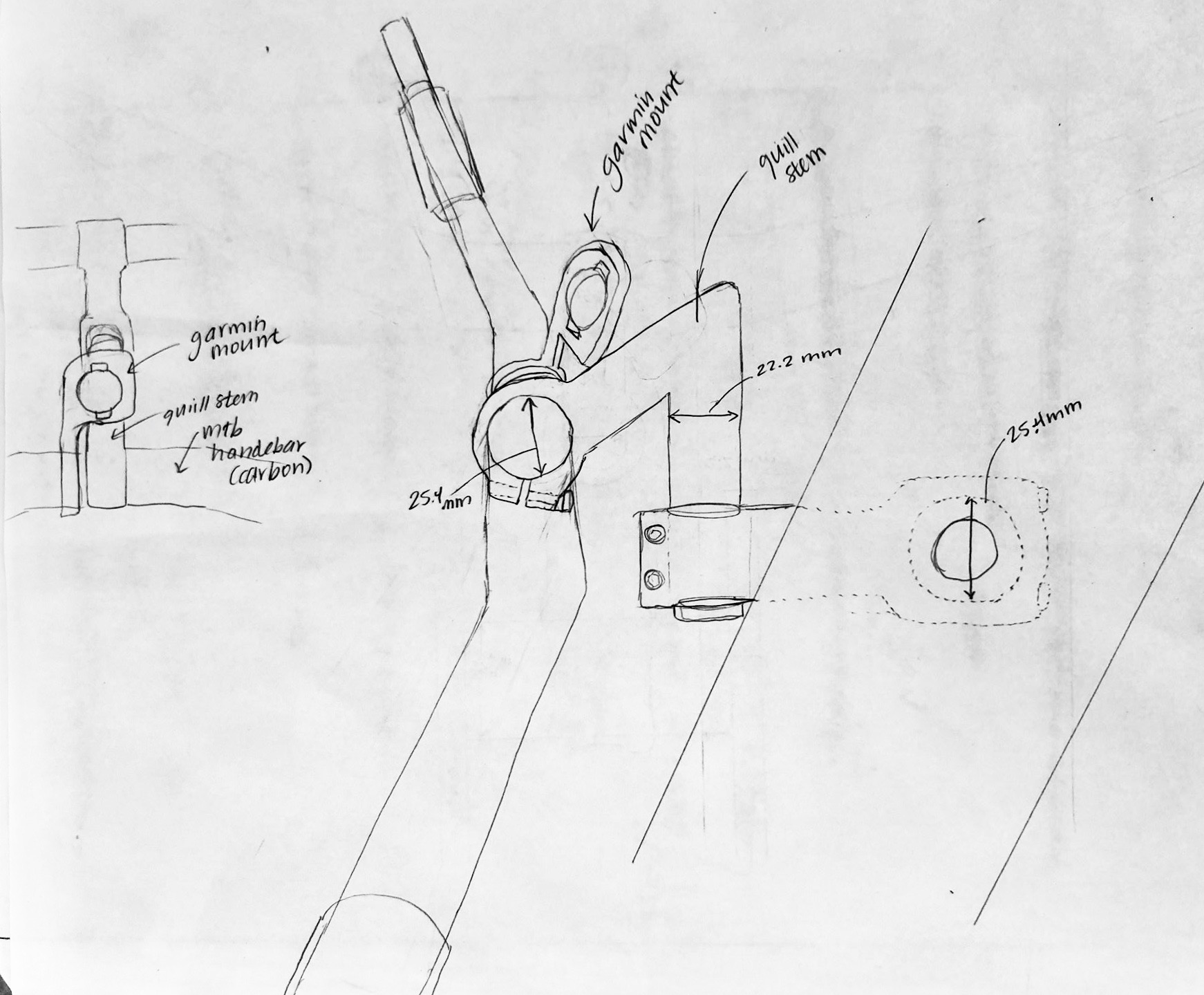

My initial idea, as a longtime cyclist, was to use a series of two stems with shims to attach the handlebars to an existing shaft which connects to the frame. This would have required sourcing a quill stem and standard stem as well as printing appropriately sized shims for the intersection of the two stems.

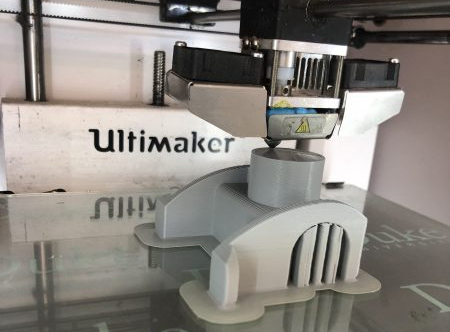

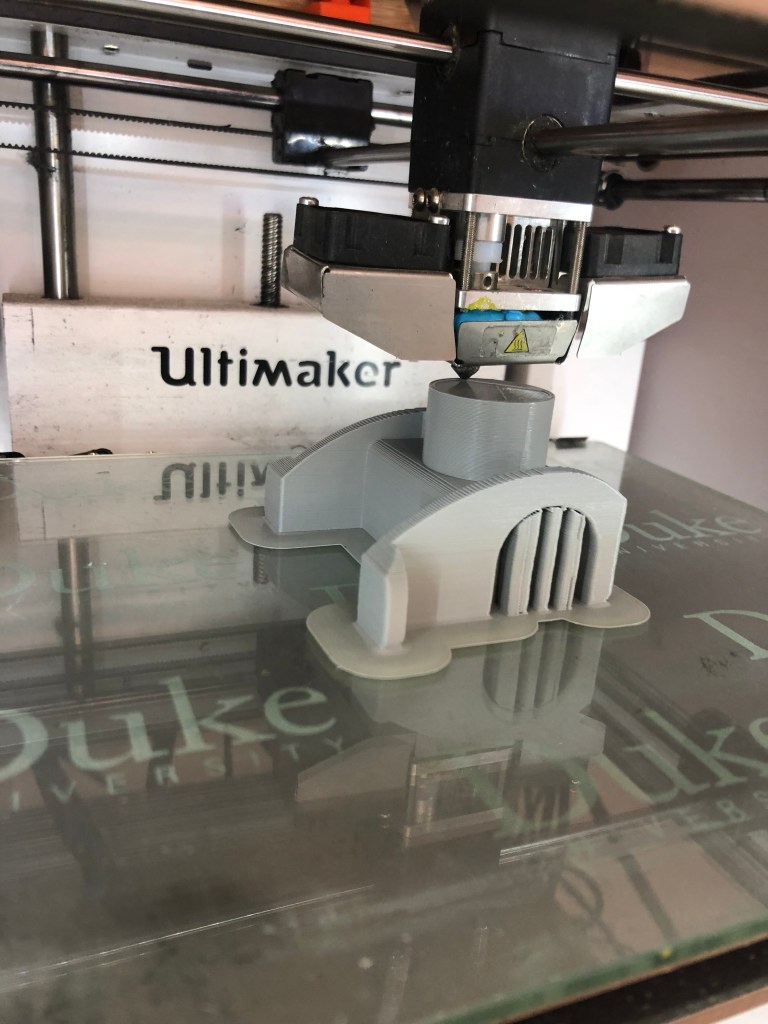

However, as our team ran out of time before a major deadline (the Ruby Arts and Tech Fair) it became necessary to create a more cost-efficient and quickly produced solution. 3D Printing was the clear choice as it is free and accessible to us.

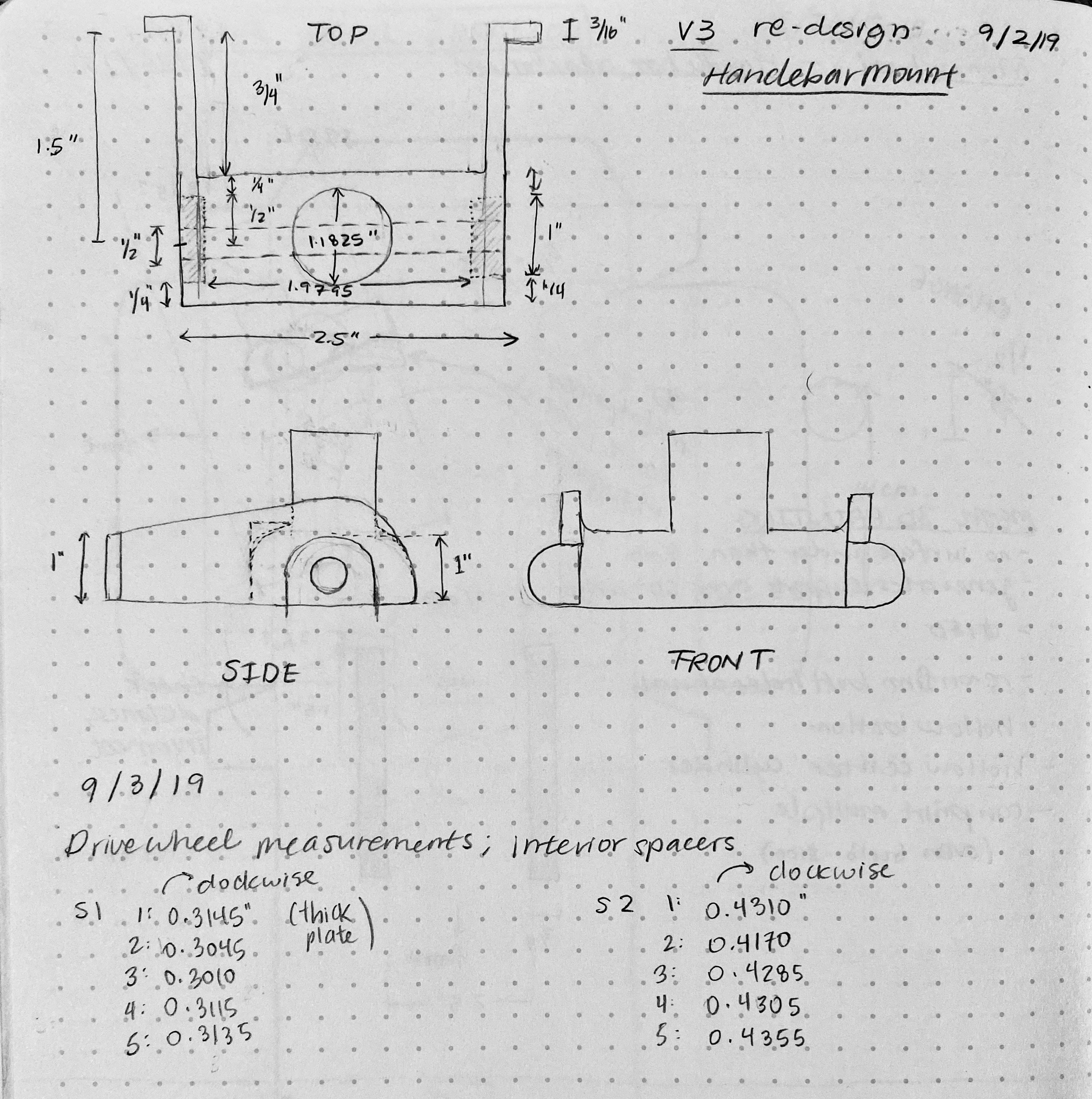

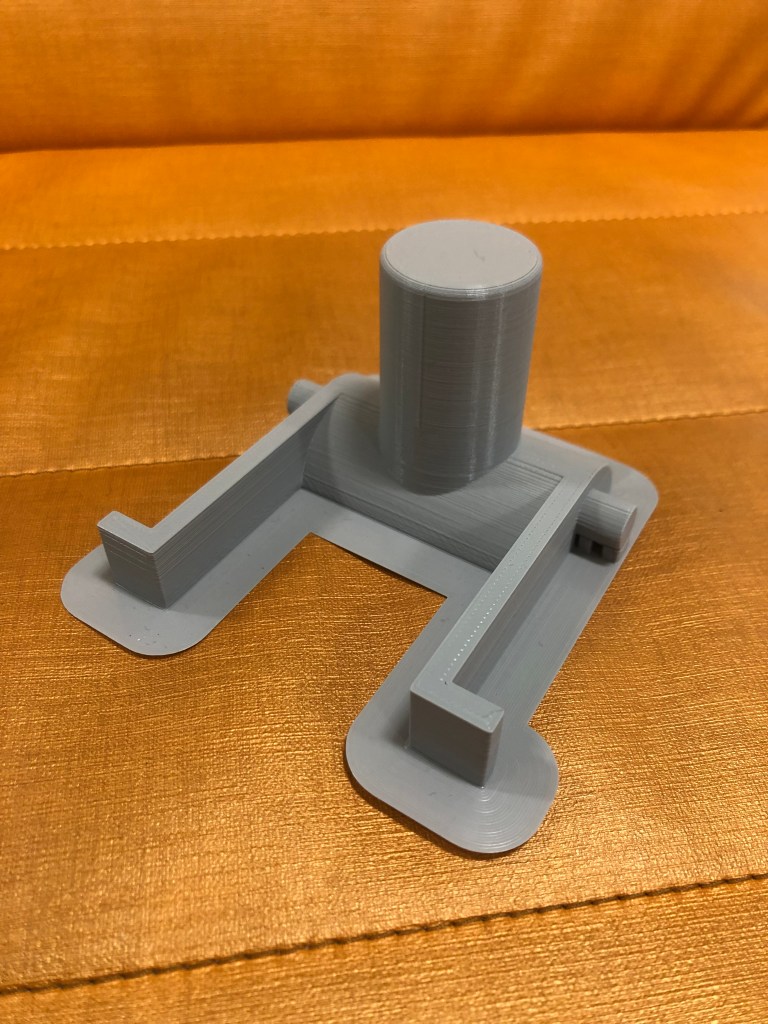

To the left is the initial prototype, based upon the left-hand drawing. Two issues became clear, that the overall width dimensions were slightly off (oops!) and that printing along the z-axis orientation was less secure as the main force experienced by the central cylinder is transverse shear. 3D Printed objects are weakest in transverse shear stress parallel to the printing plane due to the layering effect of printing.

I redesigned the part to be more aesthetically similar to the rest of the monowheel, but the transverse shear problem persisted, despite shifting the printing orientation. Our team realized that PLA, even at 100% infill, is simply not strong enough to withstand the shear and bending forces from the driver.

An alternative was quickly manufactured using a u-shaped aluminum plate that catches the handlebar stem between the two sides of the frame. As of mid-October, we will be expanding the width between the frame, therefore a new mount will need to be designed and manufactured – very likely in aluminum or steel.