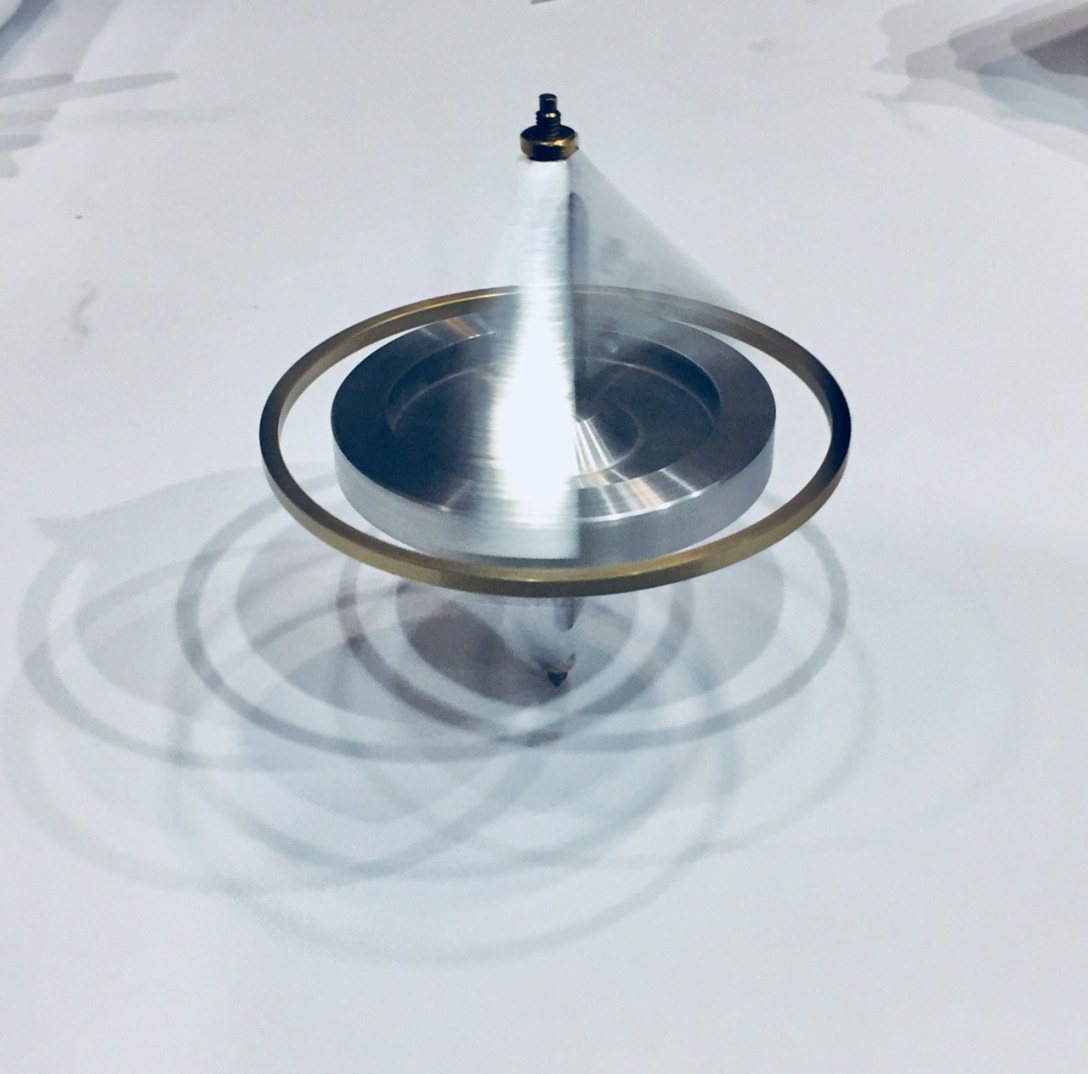

Assignment: Build a Gyroscope to the specifications provided in the given SolidWorks part files, limited modifications allowed.

The Gyroscope was held upright and mechanically driven to a starting rotation speed of 1680 rpm and released to a hard smooth base surface. The elapsed time was recorded until Gyro frame touches base surface.

I was extremely careful while machining to ensure that there was precise and accurate rotational symmetry about the spinning axis of the frame. Specifically, while milling out the ‘X’ slots of the frame, I ensured that the distance from the axis of rotation to the edges of the slot were equivalent within 0.001 inch by carefully adjusting the mill feed rate and performing slow, consistent passes of the end mill through the aluminum material.

I used powdered graphite and a Shea butter mixture applied to the interaction points between the spindle and brass bearings to decrease friction and thereby increase rotor spinning time.

During individual tests using a traditional ‘string’ method of initiating gyroscope rotation, my finished gyroscope spun upright for over 75 seconds, while the longest spinning time during our class demonstration was only 58 seconds.